5 Signs Your Hydraulic Pressure Regulator Needs Maintenance or Replacement

Hydraulic systems are the backbone of numerous industrial applications, ranging from construction and agricultural machinery to manufacturing and automotive systems. Central to their operation is the hydraulic pressure regulator—a critical component responsible for maintaining steady and accurate pressure within the system. Over time, however, even the most robust hydraulic regulators can wear down, become inefficient, or fail completely. Identifying the early warning signs of trouble can save time, prevent damage to other components, and reduce costly downtime. In this article, we’ll explore five key signs your hydraulic pressure regulator needs maintenance or replacement, with a focus on performance, safety, and longevity.

Inconsistent System Pressure

One of the most telling signs that your hydraulic pressure regulator requires attention is fluctuating or inconsistent system pressure. A properly functioning pressure regulator should maintain a consistent pressure level, ensuring that the hydraulic system operates within the intended range. When the regulator begins to fail, pressure levels may spike or drop unexpectedly, causing erratic system behavior.

This inconsistency can manifest in various ways, such as sluggish actuator movement, jerky motion, or even complete failure to actuate. These symptoms often point to internal wear or damage within the regulator’s components, such as the diaphragm, seals, or valve mechanism. The longer these issues are ignored, the more they compromise the performance of the entire hydraulic system. Performing regular hydraulic pressure regulator maintenance can prevent these problems from escalating, preserving both efficiency and safety.

In addition to performance issues, inconsistent pressure can place undue stress on other components, leading to premature wear and increased risk of hydraulic system failure. By proactively identifying and correcting pressure irregularities, operators can avoid cascading damage and extend the service life of their equipment.

Unusual Noises or Vibrations

Hydraulic systems are typically designed to operate smoothly and quietly, so any unusual noises—such as knocking, hissing, or whining—can indicate that something is amiss. These sounds often point to internal issues with the pressure regulator, such as air entrapment, valve obstruction, or damaged internal seals.

Vibrations may accompany these noises and can signal turbulence in the fluid flow or mechanical instability in the regulator assembly. If left unchecked, these vibrations can loosen fittings, fatigue metal components, and increase the risk of leaks or fractures. It’s important not to dismiss these signs as minor nuisances; they are often early indicators of deeper problems.

Conducting thorough inspections as part of routine hydraulic pressure regulator maintenance can help identify the source of unusual sounds and vibrations before they escalate. Whether it’s a blocked valve port or a deteriorating diaphragm, timely intervention can restore smooth operation and prevent more serious failures down the line.

Leaks Around the Regulator

Visible leaks are among the most obvious and serious signs of hydraulic system failure, and they often stem from problems with the pressure regulator. A leaking regulator can result from degraded seals, cracked housings, or improperly tightened fittings. Even small leaks can lead to significant performance issues, reduced system pressure, and potential contamination of the hydraulic fluid.

Leaks are not only a maintenance concern but also a major safety hazard. Hydraulic fluid is often under extreme pressure and can be harmful upon contact with skin or eyes. Additionally, leaked fluid creates slippery surfaces that increase the risk of workplace accidents.

When leaks are observed, it’s crucial to address them immediately. This may involve replacing seals, re-torquing fittings, or replacing the regulator altogether if the damage is extensive. Regular visual inspections should be part of every hydraulic pressure regulator maintenance routine to detect and correct leaks early.

Ignoring leaks can lead to reduced system efficiency, higher operating costs due to fluid loss, and damage to nearby components. More importantly, ongoing leaks often indicate that the pressure regulator is nearing the end of its service life and may soon fail entirely. Taking prompt action ensures safe, efficient, and uninterrupted hydraulic system operation.

Reduced Performance and Efficiency

Over time, a failing hydraulic pressure regulator can result in a noticeable decline in system performance and overall efficiency. This may include slower response times, reduced force output, or decreased operational precision. Operators may observe that tasks that previously took seconds now require longer cycle times, or that machines struggle to perform as effectively as they once did.

This performance drop can often be traced back to internal wear and tear within the regulator. Deposits or contamination in the hydraulic fluid may clog internal passages, while worn components may prevent the regulator from maintaining stable pressure. These issues are especially common in environments where the system operates continuously or under high loads.

Decreased efficiency doesn’t just affect productivity—it also increases operational costs. The system may consume more power to achieve the same output or require more frequent servicing due to added strain on components. In severe cases, a struggling regulator can overheat or fail, leading to unexpected downtime and expensive repairs.

Proactive hydraulic pressure regulator maintenance—including cleaning, calibration, and parts replacement—can help maintain peak performance. If maintenance fails to restore proper function, replacement may be the only option. Investing in a new, high-quality pressure regulator not only restores system efficiency but also reduces long-term operating costs.

Alarming System Warnings or Diagnostic Codes

Modern hydraulic systems are often equipped with diagnostic tools or control systems that monitor performance in real time. When a pressure regulator begins to fail, these systems may trigger warning lights, error codes, or alarms. These warnings should never be ignored, as they provide valuable insight into developing issues before catastrophic failure occurs.

For instance, a system may display warnings related to low or high pressure, fluid temperature anomalies, or reduced actuator responsiveness. These indicators often reflect problems with pressure regulation and serve as an early alert that the regulator is underperforming or malfunctioning.

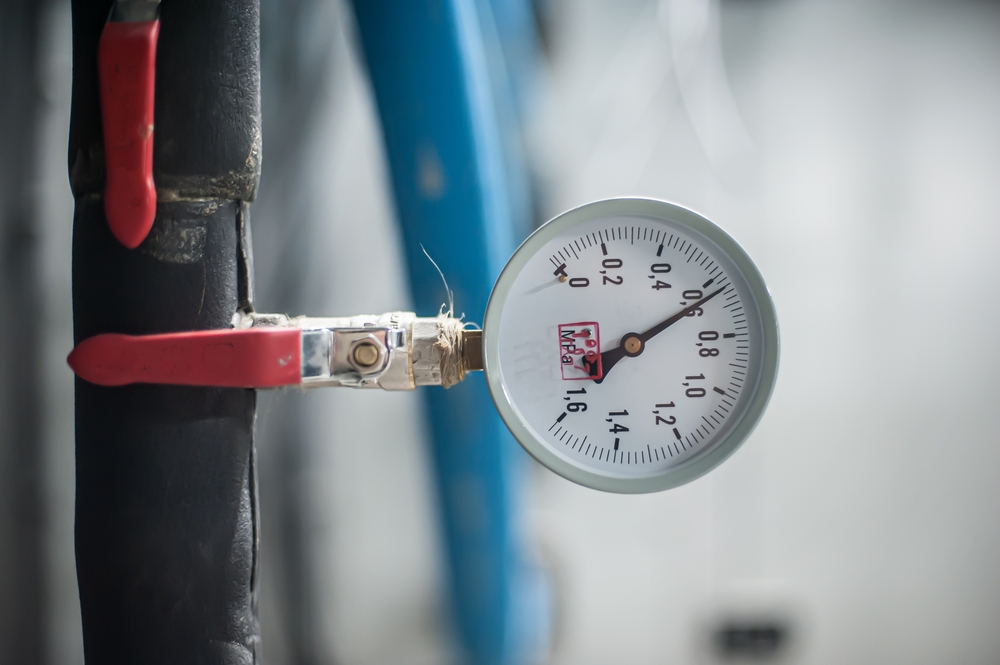

In systems without digital diagnostics, operators may need to rely on manual pressure gauges or flow meters to identify abnormalities. Regular testing and data logging can reveal trends that suggest deteriorating regulator performance, such as pressure drift or inconsistent flow rates.

Responding promptly to system warnings allows maintenance teams to isolate and address the root cause—often the pressure regulator—before additional damage occurs. If diagnostics reveal persistent or recurring faults related to pressure regulation, it’s a clear signal that the regulator should be either serviced or replaced.

Adhering to the manufacturer’s recommended maintenance schedule and incorporating advanced monitoring tools can significantly enhance early detection efforts. This ensures that maintenance or replacement is performed at the optimal time, minimizing disruption and maximizing reliability.

Conclusion

Hydraulic pressure regulators are essential to the safe, efficient, and consistent operation of hydraulic systems. Like all mechanical components, they are subject to wear and degradation over time. By recognizing the signs of trouble early—such as inconsistent pressure, unusual noises, leaks, reduced performance, and system warnings—operators can take proactive steps to perform necessary hydraulic pressure regulator maintenance or arrange for timely replacement.

Waiting too long to address these signs can lead to more extensive damage, higher repair costs, and even complete hydraulic system failure. However, with regular inspection, preventative maintenance, and a readiness to replace aging components, you can ensure the longevity, safety, and performance of your equipment. A well-maintained hydraulic system not only boosts productivity but also provides peace of mind in high-stakes industrial environments.

Whether you’re overseeing a large fleet of machines or managing a single hydraulic unit, understanding these critical warning signs empowers you to take swift, informed action—protecting both your investment and the people who rely on it every day.

Royal Brass Incorporated

Welcome Royal Brass Incorporated! We are your 3rd generation, family-owned, local hose supplier! Our family has dedicated our services to supplying northern California with all types of hoses, fittings, flanges, regulators, valves, adapters, and gauges. We pride ourselves on having the most extensive inventory in northern California. Our inventory ensures that we can fix most products on site, the same day. Here at Royal Brass Incorporated, we only hire qualified individuals who are trained in factory sales. Our fully stocked warehouses ensure that we can fill your hydraulic and pneumatic hose, tubing, and fitting needs on time, every time. High-quality customer service is our goal and has been since 1952. Stop by or contact us today!

Categorised in: Pressure Regulators