When to Upgrade to a Reinforced Hydraulic Hose

Hydraulic hoses are the unsung heroes of countless machines, vehicles, and industrial systems. They transport pressurized fluid that powers heavy equipment, construction vehicles, and manufacturing tools. While standard hoses serve many everyday applications, there comes a time when upgrading to a reinforced hydraulic hose is not just beneficial but critical. Understanding when that time has arrived can protect your equipment, minimize downtime, and save substantial repair costs. This article explores precisely when you should consider stepping up to a reinforced hydraulic hose or even a heavy duty hydraulic hose, covering essential technical and operational factors that make the upgrade worthwhile.

Hydraulic Hose Construction and Reinforcement

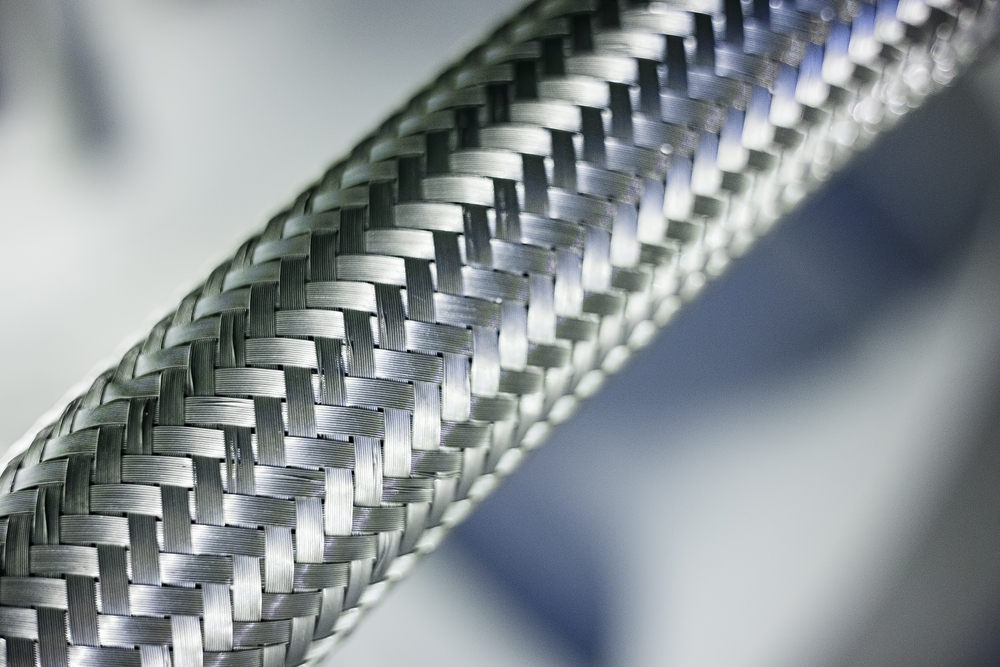

At the most basic level, a hydraulic hose consists of three key layers: the inner tube, the reinforcement layer, and the outer cover. The reinforcement is what sets a reinforced hydraulic hose apart from lighter-duty variants. Typically constructed with multiple layers of braided or spiral-wound wire, the reinforcement allows the hose to withstand higher pressures and more demanding conditions without bursting or collapsing.

Reinforced hydraulic hoses are designed to manage intense pulses of hydraulic fluid under high pressure, which would quickly degrade a conventional hose. This reinforced construction also gives the hose far greater resistance to abrasion, heat, chemicals, and environmental stressors. For operators and maintenance professionals, this means peace of mind and reliability even under punishing conditions. When your application demands continuous exposure to high pressure or frequent pressure surges, standard hoses simply do not deliver the same durability or safety, making a reinforced or heavy duty hydraulic hose a clear choice.

Signs That It’s Time to Upgrade

Over time, hydraulic hoses inevitably show wear. However, if you notice accelerated cracking, blistering, or even minor leaks along the hose, that should be an immediate red flag. These symptoms are often caused by pressure spikes exceeding the hose’s rated working pressure or by repeated flexing under high-pressure conditions. If your operations involve sharp pressure cycles — for example, in construction excavators, hydraulic presses, or mining drills — these stresses will weaken non-reinforced hoses far faster than their reinforced counterparts.

Another warning sign is when equipment requires greater flow capacity or operates with increasingly demanding hydraulic pressures due to modernized upgrades or performance modifications. If you retrofit machinery to achieve higher output, the hydraulic hoses must match this upgraded performance. Sticking with a standard hose may be tempting to save costs, but doing so poses safety hazards, including catastrophic hose bursts or failures that could shut down the entire system.

Finally, you should consider an upgrade if your equipment is being deployed in more extreme environments — such as locations with abrasive debris, elevated temperatures, or corrosive fluids. Reinforced hydraulic hoses excel under these harsh conditions and will help extend service intervals, providing better long-term value for your maintenance budget.

Benefits of Reinforced Hydraulic Hoses

The main benefit of a reinforced hydraulic hose is its ability to safely withstand far higher pressures, which immediately improves safety margins. These hoses often come with enhanced temperature tolerances and superior kink resistance. Reinforced layers maintain the shape of the hose under stress, preserving steady fluid flow without collapse or deformation.

In addition, the durability of a reinforced or heavy duty hydraulic hose means fewer maintenance interventions. Standard hoses in demanding applications might require replacement every few months, while a reinforced hose could last significantly longer, reducing downtime and associated labor costs. This improved service life has a tangible impact on profitability, especially in industries where downtime can cost thousands of dollars per hour.

Beyond performance, there’s also a compliance advantage. Many industrial or mobile hydraulic systems must meet specific safety standards, such as ISO or SAE ratings. Reinforced hoses are frequently designed and tested to these higher benchmarks, helping you stay in compliance with regulatory requirements while protecting your team and equipment.

Choosing the Right Reinforced Hydraulic Hose

Once you recognize the need to upgrade, selecting the proper reinforced hydraulic hose becomes the next challenge. It is crucial to match the hose to your equipment’s operating pressure, temperature range, and fluid compatibility. Consult the hydraulic system’s specifications, paying close attention to the rated working pressure and the maximum pressure spikes expected during operation. This will help you choose a hose with appropriate reinforcement layers, whether that is two-wire braided reinforcement for moderate demands or spiral-wound multi-wire reinforcement for extreme high-pressure systems.

It is also important to consider the flexibility of the hose. A heavy duty hydraulic hose with multiple spiral layers may be more rigid, which could create routing challenges in tight spaces. In these cases, selecting a hose with flexible yet reinforced construction can be the best compromise.

Working with a reputable supplier or hydraulic systems engineer can help you evaluate options. They can guide you on hose assembly techniques, correct fittings, and protective coverings like guards or sleeves that further extend hose life. Investing in quality up front pays dividends by avoiding premature failures or costly repairs.

Maintaining Your Upgraded Hydraulic Hose

Even after upgrading to a reinforced hydraulic hose, proper maintenance is still critical. Periodic inspections should include checking for external abrasion, oil seepage, blistering, and kinking. Hoses should be routed away from sharp edges or high-heat sources wherever possible and supported properly to prevent rubbing or excessive bending.

Contamination of the hydraulic fluid can also dramatically shorten hose life, so regular fluid sampling and filtration checks should become part of your preventive maintenance routine. Reinforced hoses are far more durable, but no hose is immune to the damage caused by contaminated hydraulic oil. Keeping the system clean protects not just the hose but every other hydraulic component as well.

Be sure to document hose replacements and any incidents of failure. Over time, this maintenance history provides powerful insight into your equipment’s performance and may help you identify patterns of hose wear that could indicate deeper system problems.

Conclusion

In many industries — from construction to manufacturing and agriculture — a reinforced hydraulic hose is an essential upgrade to safeguard against unplanned downtime and dangerous failures. Recognizing the signs of hose deterioration, choosing a properly rated reinforced hose, and then maintaining it with disciplined care will deliver the performance, safety, and reliability that modern hydraulic systems demand.

If your equipment operates with higher pressures, experiences regular hydraulic pulses, or faces harsh environmental challenges, upgrading to a reinforced or heavy duty hydraulic hose should be on your maintenance checklist. Investing in this upgrade is not only a technical improvement but a smart strategic decision for your business.

Royal Brass Incorporated

Welcome Royal Brass Incorporated! We are your 3rd generation, family-owned, local hose supplier! Our family has dedicated our services to supplying northern California with all types of hoses, fittings, flanges, regulators, valves, adapters, and gauges. We pride ourselves on having the most extensive inventory in northern California. Our inventory ensures that we can fix most products on site, the same day. Here at Royal Brass Incorporated, we only hire qualified individuals who are trained in factory sales. Our fully stocked warehouses ensure that we can fill your hydraulic and pneumatic hose, tubing, and fitting needs on time, every time. High-quality customer service is our goal and has been since 1952. Stop by or contact us today!

Categorised in: Hydraulic Hose