The Role of Anti-Abrasion Sleeves in Hose Longevity

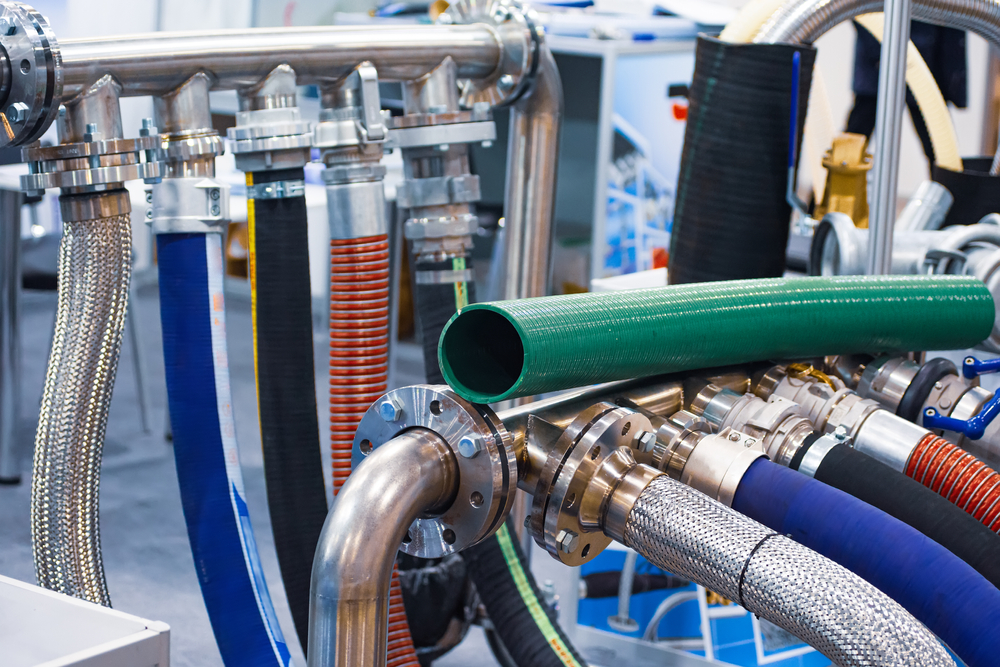

In demanding industrial environments, hydraulic and pneumatic hoses face constant threats from friction, vibration, and environmental exposure. Whether they’re used in construction equipment, manufacturing lines, or agricultural machinery, hoses are critical to keeping systems running efficiently. Yet, one of the most common causes of hose failure isn’t internal pressure or fluid leaks: it’s abrasion.

At Royal Brass Inc., we understand that even the highest-quality hoses need protection from everyday wear and tear. That’s where hose protection sleeves come in. These anti-abrasion covers are designed to shield hoses from external damage, significantly extending their lifespan and improving overall system reliability.

In this guide, we’ll explore why hose abrasion sleeves are essential, how they work, and what types of sleeves best suit different applications.

Why Abrasion Is a Major Threat to Hoses

When hydraulic or pneumatic hoses rub against hard surfaces, sharp edges, or other components, they gradually lose their outer layer. This process, known as abrasion, weakens the hose’s structure and can eventually expose its reinforcement or inner tube. Once that happens, the hose is vulnerable to leaks, bursts, and catastrophic failure.

The problem is especially severe in environments where hoses are in constant motion or exposed to rough conditions, such as:

-

Construction and mining equipment where hoses move with heavy machinery.

-

Manufacturing facilities where hoses contact metal surfaces or are bundled together.

-

Forestry, agricultural, or oilfield operations where hoses are exposed to dirt, rocks, and weather.

Without protection, hoses in these settings can fail prematurely, leading to costly downtime, fluid loss, and even safety hazards for operators.

How Hose Protection Sleeves Work

Hose protection sleeves act as a barrier between the hose’s surface and its environment. They absorb friction and deflect contact with abrasive materials, preventing direct damage to the hose cover.

Depending on the type of sleeve, they may also provide added benefits such as:

-

UV protection: Preventing degradation from prolonged sunlight exposure.

-

Chemical resistance: Shielding hoses from oil, grease, and industrial fluids.

-

Temperature regulation: Offering insulation against extreme heat or cold.

-

Containment: Containing leaks or bursts to protect surrounding equipment and personnel.

The right sleeve can extend a hose’s service life by years, reducing replacement frequency and maintenance costs.

Types of Hose Abrasion Sleeves

Not all sleeves are created equal. Selecting the right product depends on your equipment, environment, and application. At Royal Brass Inc., we supply a variety of hose abrasion sleeves tailored to different operational needs.

1. Nylon Protective Sleeves

Nylon sleeves are one of the most common and versatile types of hose protection. They are lightweight, flexible, and resistant to wear, making them ideal for general-purpose applications.

Key Benefits:

-

Excellent abrasion resistance.

-

Withstands exposure to oils, solvents, and fuels.

-

Resists UV rays and weather conditions.

-

Easy to install over existing hoses or bundles.

These sleeves are perfect for mobile hydraulic systems, forklifts, and agricultural machinery where flexibility and durability are equally important.

2. Polyester or Polypropylene Sleeves

Polyester and polypropylene sleeves provide cost-effective protection for hoses used in less demanding environments. While they don’t offer the same level of abrasion resistance as nylon, they still deliver solid performance for moderate-duty applications.

Key Benefits:

-

Lightweight and affordable.

-

Resistant to chemicals and most industrial fluids.

-

Good flexibility and easy installation.

These are commonly used for hydraulic return lines, pneumatic systems, or machinery where abrasion exposure is moderate.

3. Heavy-Duty Textile Sleeves

For harsh industrial environments, heavy-duty woven textile sleeves are the go-to solution. These are made from tightly woven fibers designed to withstand constant friction and impact.

Key Benefits:

-

Superior abrasion resistance for extreme-duty applications.

-

Can handle high temperatures and demanding conditions.

-

Provides containment in case of hose bursts or leaks.

-

Meets ISO 6945 abrasion resistance standards.

They’re often used in mining, oil and gas, and heavy construction equipment where hoses encounter constant vibration and high-pressure operation.

4. Spiral Wrap Protection

While not technically a sleeve, spiral wrap provides similar protection for hoses that require flexibility and accessibility. Spiral wraps are made from polyethylene or nylon and wrap around the hose in a coiled design.

Key Benefits:

-

Allows easy routing and bundling of multiple hoses.

-

Offers abrasion protection and organization.

-

Can be installed without disconnecting the hose.

-

Ideal for dynamic machinery with frequent movement.

Spiral wraps are excellent for applications where hoses move frequently or need to be bundled together, such as in excavators or agricultural tractors.

The ROI of Hose Protection Sleeves

Investing in hose protection sleeves is one of the most cost-effective ways to extend hose life and reduce maintenance expenses. While the upfront cost is minimal compared to the price of hose replacement or equipment downtime, the long-term savings can be significant.

1. Reduced Downtime

A failed hose can halt an entire production line or immobilize heavy equipment. By protecting hoses from abrasion, sleeves prevent unplanned outages and keep operations running smoothly.

2. Lower Replacement Costs

Hoses exposed to friction or harsh environments often need replacement long before their rated service life. Sleeves help hoses reach or exceed their expected lifespan, reducing replacement frequency and associated labor costs.

3. Improved Safety

Burst or leaking hoses pose serious safety hazards, especially in hydraulic systems operating at high pressures. Abrasion sleeves help prevent these failures, protecting operators and equipment from potential harm.

4. Cleaner Work Environment

In case of a hose rupture, containment sleeves can help limit fluid spray, keeping nearby components and workers safer. This also simplifies cleanup and reduces environmental risks.

5. Enhanced Professional Appearance

Well-protected hoses not only perform better but also present a cleaner, more professional image for your equipment. This is especially important for OEMs and service providers who want to demonstrate quality and reliability to their customers.

Choosing the Right Sleeve for Your Application

Selecting the correct sleeve involves more than just matching diameter sizes. At Royal Brass Inc., we help clients evaluate key factors to ensure optimal performance and protection.

Environmental Conditions

Consider exposure to heat, UV rays, moisture, chemicals, and debris. For example, nylon sleeves are great for outdoor use, while textile sleeves may perform better in high-heat environments.

Level of Abrasion

Assess how much friction or movement the hose experiences. Stationary hoses with limited contact may need only light-duty protection, while moving hydraulic lines require heavy-duty sleeves.

Installation Preferences

Some sleeves can be installed over existing hoses without disconnecting fittings, while others require assembly during installation. Spiral wraps offer quick installation, while woven sleeves provide maximum protection.

Hose Configuration

For systems with multiple hoses running side-by-side, consider sleeves designed for bundling. These not only prevent abrasion but also improve organization and safety.

Our team provides tailored recommendations for your specific equipment, ensuring your investment delivers the best possible performance.

Installation Tips for Maximum Protection

Proper installation is just as important as selecting the right sleeve. Here are a few best practices to get the most out of your hose abrasion sleeves:

-

Measure accurately: Choose a sleeve slightly larger than the hose’s outer diameter for easy installation.

-

Secure the ends: Use clamps, zip ties, or heat-shrink bands to keep the sleeve in place and prevent slipping.

-

Avoid sharp bends: Ensure the hose and sleeve are routed to minimize sharp angles that can cause friction.

-

Inspect regularly: Check for wear or damage during maintenance intervals and replace sleeves as needed.

At Royal Brass Inc., we can also assist with on-site consultations and product selection, ensuring your hoses are properly protected from day one.

Why Choose Royal Brass Inc. for Hose Protection Solutions

For over 70 years, Royal Brass Inc. has been a trusted supplier of fluid power and industrial components. We don’t just sell parts: we provide complete solutions. Our expertise spans hydraulic systems, fittings, adapters, and protective accessories, including a wide range of hose protection sleeves designed for every industry.

When you work with us, you get:

-

Premium Products: We source sleeves from top manufacturers known for quality and performance.

-

Technical Expertise: Our team understands the challenges of heavy-duty applications and can recommend the right products for your setup.

-

Inventory and Availability: We stock a comprehensive selection of hose sleeves, wraps, and guards for immediate delivery.

-

Customer Support: From consultation to installation, we’re committed to helping you reduce downtime and maximize hose longevity.

Our mission is simple: to help our customers extend equipment life, improve safety, and lower maintenance costs through smart, reliable solutions.

Protect Your Hoses, Protect Your Bottom Line

In industrial and hydraulic systems, the smallest component often plays the biggest role in reliability. Hose protection sleeves may seem like a minor addition, but they are a critical safeguard against one of the most common causes of hose failure: abrasion.

By investing in high-quality hose abrasion sleeves, you extend the life of your hoses, improve equipment safety, and ensure consistent performance. It’s a simple, affordable solution that pays off in reduced downtime, lower costs, and greater peace of mind.

At Royal Brass Inc., we’re here to help you choose and implement the right protective solutions for your equipment. Contact us today to learn more about our full range of hose protection products and how we can help you maximize hose longevity in your operation.

Categorised in: Hydraulic Hose, Hydraulic Hose Fittings