How to Choose the Right Pneumatic Quick Coupler for your Specific Needs

Pneumatic quick couplers play a crucial role in connecting and disconnecting air tools, hoses, and other pneumatic equipment quickly and efficiently. However, with various types, sizes, and configurations available, choosing the right pneumatic quick coupler for your specific needs can be overwhelming. In this guide, we’ll explore key factors to consider when selecting pneumatic couplers, providing valuable insights into “how to choose pneumatic couplers” and “choosing the right pneumatic disconnect” to meet your requirements.

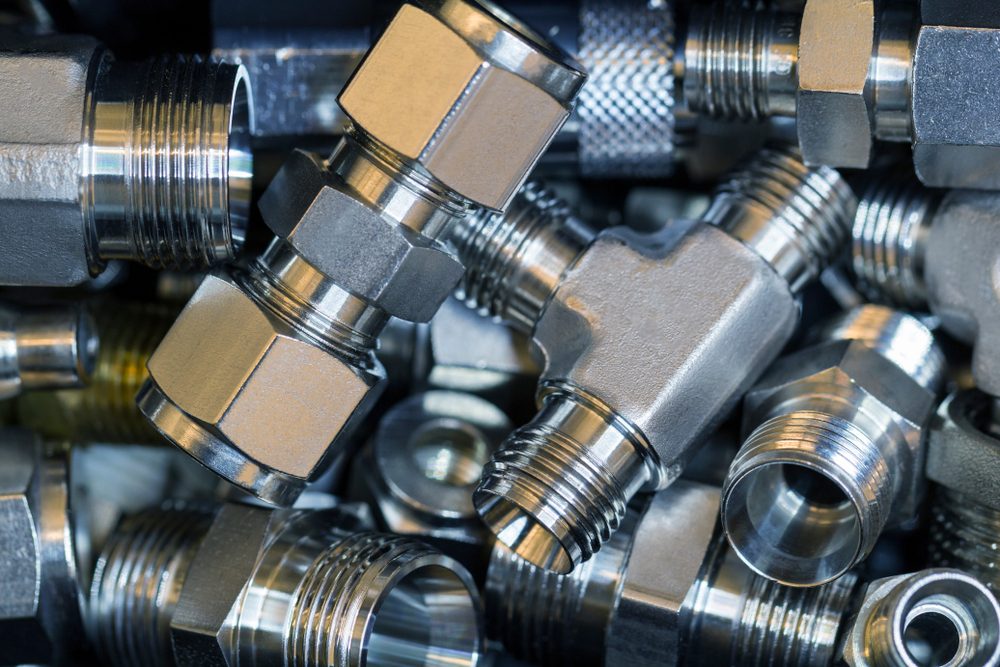

Understanding Pneumatic Quick Couplers

Pneumatic quick couplers, also known as pneumatic quick disconnects or air couplers, are devices used to connect and disconnect pneumatic tools and equipment from air supply lines rapidly. These couplers consist of two main components: a male plug and a female socket, each equipped with compatible fittings that allow for a secure and leak-free connection. Pneumatic couplers come in various types, including push-to-connect, twist-lock, and claw-type couplings, each offering unique features and benefits for different applications.

Considerations for Choosing Pneumatic Couplers

When selecting pneumatic quick couplers for your specific needs, several factors should be taken into account:

- Compatibility: Ensure compatibility between the coupler and your pneumatic tools and equipment. Consider factors such as thread size, connection type, and flow capacity to ensure a secure and reliable connection.

- Pressure Rating: Check the pressure rating of the pneumatic coupler to ensure it can handle the operating pressure of your pneumatic system. Choose couplers with a pressure rating that exceeds the maximum operating pressure to prevent leaks or failure under high-pressure conditions.

- Flow Capacity: Consider the flow capacity of the pneumatic coupler, which determines the maximum airflow rate that can pass through the coupling. Choose couplers with adequate flow capacity to prevent restrictions and ensure optimal performance of your pneumatic tools and equipment.

- Material Construction: Pay attention to the material construction of the pneumatic coupler, as it affects durability, corrosion resistance, and compatibility with different media. Common materials used for pneumatic couplers include brass, steel, aluminum, and various types of plastics.

- Locking Mechanism: Evaluate the locking mechanism of the pneumatic coupler, which determines how securely the plug and socket are held together. Choose couplers with robust locking mechanisms that provide a secure connection and prevent accidental disengagement during operation.

Types of Pneumatic Quick Couplers

There are several types of pneumatic quick couplers available, each offering unique features and advantages:

- Push-to-Connect Couplers: These couplers feature a simple push-to-connect design that allows for quick and effortless connection without the need for tools. Push-to-connect couplers are ideal for applications where fast and frequent connections are required.

- Twist-Lock Couplers: Twist-lock couplers require a twisting motion to connect and disconnect, providing a secure and reliable connection. These couplers are often used in high-pressure applications or environments where accidental disconnection is a concern.

- Claw-Type Couplers: Claw-type couplers utilize a claw-like mechanism to grip and hold the plug in place, ensuring a secure connection. These couplers are commonly used in industrial applications and offer excellent resistance to vibration and shock.

- Safety Couplers: Safety couplers incorporate additional features, such as automatic shut-off valves or pressure relief mechanisms, to prevent accidental disconnection and minimize the risk of injury or damage.

Application-Specific Considerations

When choosing pneumatic quick couplers, it’s essential to consider the specific requirements and conditions of your application:

- Industrial Applications: For industrial applications involving heavy-duty machinery and equipment, choose robust and durable couplers capable of withstanding high pressures, temperatures, and harsh environments.

- Automotive Applications: Automotive applications often require quick and frequent connections for pneumatic tools and equipment. Choose couplers with ergonomic designs and easy-to-use locking mechanisms for efficient operation in automotive workshops and garages.

- HVAC and Plumbing: In HVAC and plumbing applications, select couplers with leak-free seals and corrosion-resistant materials to ensure reliable performance and longevity in humid or corrosive environments.

- DIY and Home Use: For DIY projects and home use, opt for versatile and user-friendly couplers that are easy to connect and disconnect without specialized tools or equipment.

Summary

Choosing the right pneumatic quick coupler for your specific needs is essential for ensuring efficient operation, reliable performance, and safety in pneumatic systems and applications. By considering factors such as compatibility, pressure rating, flow capacity, material construction, and locking mechanism, you can select the most suitable couplers for your requirements. Whether you’re working in industrial settings, automotive workshops, HVAC installations, or DIY projects, the right pneumatic couplers will facilitate quick and hassle-free connections, enhancing productivity and performance in your pneumatic operations.

Royal Brass Incorporated

Here at Royal Brass Incorporated, we understand the importance of choosing the right pneumatic quick couplers to ensure the efficiency and safety of your pneumatic systems. Our expert team is here to guide you through the selection process, providing personalized recommendations based on your specific needs and applications. Whether you need couplers for industrial machinery, automotive tools, HVAC systems, or DIY projects, we have the perfect solutions to enhance your operations. Reach out to us today and let us help you find the ideal pneumatic quick couplers for your requirements.

Categorised in: Couplers