Proper Maintenance and Care for Hydraulic Flanges to Extend Their Lifespan

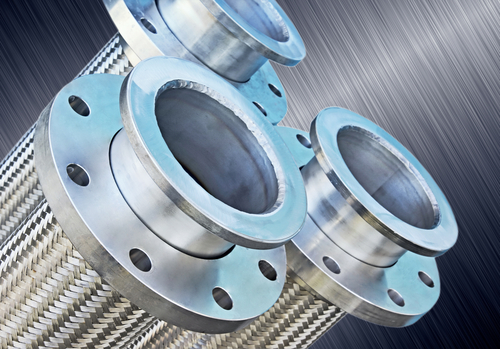

Hydraulic flanges are an essential component in hydraulic systems, as they serve as connectors between hoses, pipes, and tubes. Proper maintenance and care of hydraulic flanges are crucial to ensure the smooth functioning and longevity of the entire hydraulic system. In this blog, we will discuss the importance of maintaining hydraulic flanges and provide tips on how to properly care for them to extend their lifespan.

Importance of Maintaining Hydraulic Flanges

Hydraulic flanges play a critical role in hydraulic systems by providing a secure and leak-proof connection between various components. When hydraulic flanges are not properly maintained, they can develop leaks, become damaged, or wear out prematurely, leading to system inefficiencies, downtime, and potential safety hazards. Regular maintenance and care of hydraulic flanges are essential to prevent these issues and ensure the optimal performance of the hydraulic system.

Inspecting Hydraulic Flanges Regularly

One of the key components of proper maintenance for hydraulic flanges is regular inspection. Inspecting hydraulic flanges for signs of wear, damage, or leaks is essential to identify potential issues early on and address them before they escalate. During inspections, look for cracks, corrosion, loose bolts, or other signs of damage that may compromise the integrity of the flanges. If any issues are identified, take immediate action to repair or replace the affected flanges to prevent further damage to the hydraulic system.

Cleaning and Lubricating Hydraulic Flanges

Keeping hydraulic flanges clean and properly lubricated is another important aspect of maintenance. Dirt, debris, and other contaminants can accumulate on hydraulic flanges over time, leading to increased friction and wear. Regularly clean hydraulic flanges using a mild detergent and water to remove any buildup of dirt or grime. Additionally, applying a thin layer of lubricant to the flanges can help reduce friction, prevent corrosion, and extend the lifespan of the flanges.

Tightening Bolts and Fasteners

Proper torque on bolts and fasteners is crucial for ensuring the secure connection and sealing of hydraulic flanges. Over time, bolts and fasteners can become loose due to vibration or thermal expansion and contraction, which can lead to leaks or damage to the flanges. Regularly check the tightness of bolts and fasteners on hydraulic flanges using a torque wrench and tighten them to the manufacturer’s specifications if necessary. Ensuring that bolts and fasteners are properly tightened will help prevent leaks and maintain the integrity of the hydraulic system.

Replacing Gaskets and Seals

Gaskets and seals play a critical role in ensuring the leak-proof seal of hydraulic flanges. Over time, gaskets and seals can become worn out, damaged, or compressed, leading to leaks or loss of pressure in the hydraulic system. Regularly inspect gaskets and seals for signs of wear or damage, such as cracks, tears, or deformation, and replace them as needed. Using high-quality gaskets and seals that are compatible with the hydraulic fluid and operating conditions will help maintain the efficiency and reliability of the hydraulic system.

Avoiding Overpressurization

One common cause of damage to hydraulic flanges is overpressurization of the hydraulic system. Excessive pressure can put stress on the flanges, causing them to deform, crack, or fail. To prevent overpressurization, ensure that the hydraulic system is operating within the recommended pressure limits specified by the manufacturer. Use pressure relief valves or pressure gauges to monitor the pressure in the hydraulic system, and take corrective action if pressure levels exceed the safe operating range. By avoiding overpressurization, you can help protect hydraulic flanges from damage and prolong their lifespan.

Protecting Hydraulic Flanges from Environmental Factors

Environmental factors such as extreme temperatures, moisture, chemicals, and abrasive materials can have a detrimental impact on hydraulic flanges. It is important to protect hydraulic flanges from these factors to prevent corrosion, erosion, or other forms of damage. Consider installing protective covers or shields around hydraulic flanges to shield them from moisture, debris, or other environmental hazards. Additionally, storing hydraulic flanges in a clean, dry, and climate-controlled environment when not in use can help prolong their lifespan and prevent premature wear.

Training and Safety Practices

Proper maintenance and care of hydraulic flanges also involve training personnel on best practices for handling and servicing hydraulic systems. Ensure that employees who work with hydraulic flanges are trained on how to inspect, clean, lubricate, and replace components safely and correctly. Emphasize the importance of following safety protocols, wearing appropriate personal protective equipment, and using proper tools and equipment when servicing hydraulic flanges. By promoting a culture of safety and providing ongoing training, you can help prevent accidents, injuries, and costly damage to hydraulic systems.

Summary

Proper maintenance and care of hydraulic flanges are essential for ensuring the longevity and performance of hydraulic systems. By regularly inspecting hydraulic flanges, cleaning and lubricating them, tightening bolts and fasteners, replacing gaskets and seals, avoiding overpressurization, protecting them from environmental factors, and promoting training and safety practices, you can help extend the lifespan of hydraulic flanges and prevent system failures. Investing time and resources in maintaining hydraulic flanges will not only save you money in the long run but also ensure the reliability and efficiency of your hydraulic system.

Need Hose & Fittings Specialists in San Jose, CA?

Welcome Royal Brass Incorporated! We are your 3rd generation, family-owned, local hose supplier! Our family has dedicated our services to supplying northern California with all types of hoses, fittings, flanges, regulators, valves, adapters, and gauges. We pride ourselves on having the most extensive inventory in northern California. Our inventory ensures that we can fix most products on site, the same day. Here at Royal Brass Incorporated, we only hire qualified individuals who are trained in factory sales. Our fully stocked warehouses ensure that we can fill your hydraulic and pneumatic hose, tubing, and fitting needs on time, every time. High-quality customer service is our goal and has been since 1952. Contact us today!

Categorised in: Flanges